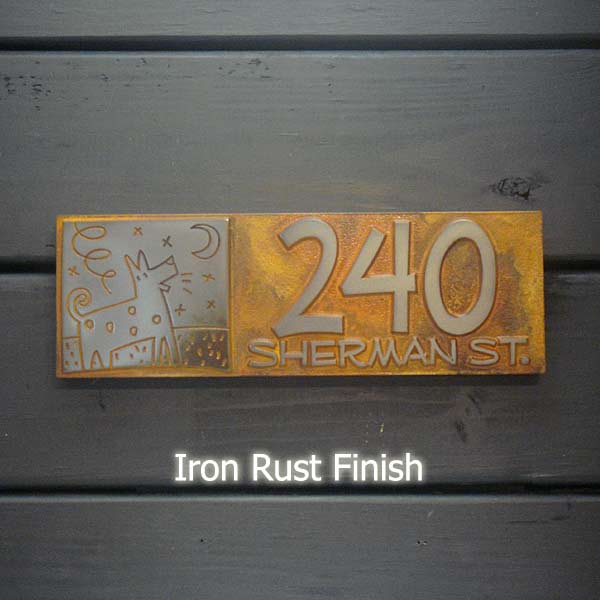

The Atlas Signs and Plaques website features over 300 complete, customizable sign options that are available to you at the push of a button.

Our website features many, many sign designs that are embedded in our database and ready to be customized. Each sign is like a burnable CD—the foundation (the CD disk, or sign) needs data (your custom text). Once those two requisites are met, smooth sailing ensues.

To help your shopping experience here are a handful of pointers and reminders.

I found the perfect sign on your webpage. How do I customize it?

This is very easily done. To make a sign yours simply find the sign you like and pull up the sign’s page. On this page you will find a box roughly halfway down that says: “Customize Text. UPPER & lower CaSe”. Enter your custom text here, paying SPECIAL attention to ensure all the text is exactly the way you want it. Once this is done, you can complete the order. Our designers will take care of the rest.

But what if I don’t find something I like on your website?

A common question. If you want something else you can send us your custom idea. Simply email your ideas to us (janey@atlassignsandplaques (MAKE SURE to include: height, width, budget, text, icons, etc.)) or you can submit a custom request by following the orange text on the leftmost column of our homepage. This links you to a page asking for specific details. Fill that page out to the best of your ability and send it to us. Once we receive your request we will contact you via email and begin a correspondence.

What if my text will not fit the sign?

For 95% of our signs this is not a problem. For the rest, like memorial and phrase plaques, we ask that you use restraint when filling in your custom text. Say ONLY what needs to be said using your best spatial judgment. We will do our very best to format your sign and your text in as beautiful a manner as possible. If your text does not fit, we will contact you for edits.

How Do I Submit a Custom Graphic Design?

We accept images in: Adobe Illustrator (ai), EPS, or vectorized PDF. (Vectorized PDF means that the file was created in Illustrator and then saved as a PDF.) Some CAD/CAM formats (DWG or DXF) are usually ok. However, even these acceptable file formats are not without some conditions. All text must be converted to outlines. Artwork should be vectorized. Rasterized images (common to photo editing software) are not acceptable. Caution should be used to assure that lines are joined (welded), and that there are not multiple overlaid lines. Embedded or linked files are equally unacceptable.

How Can I Support Atlas Signs and Plaques?

The best way to support us is to buy a sign. That’s not always feasible. Another real way to support us is to follow us on Facebook and Twitter. Social media matters, and we are very grateful for every fan.

That about does it! If you have any questions please leave them in the comment space below.