How We Make ’em

The signs and plaques that we create are not castings from a dirty polluting foundry.

Our signs and plaques have a base of modern High Density Urethane (HDU) board. This is a product that was developed for the aerospace industry and has been used for signage for over 40 years.

We coat our HDU signs and plaques with a cold applied, real metal coating that is in use world-wide as an architectural and industrial coating. It is a well-proven, tough, and beautiful coating that gives the look of cast metal without the limitations. Read our blog post about the metal coating we use.

Our signs and plaques are very durable, but will not stand up repeated abuse. If you wish to embed a plaque in the ground, hit it with a mower, or look at it in 500 years, you should order a foundry-cast plaque. We are happy to supply these, but expect to pay 4-5 times as much as the affordable plaques we create using our proven methods.

When you receive your order, you will notice that it is light weight. Since it is HDU with a thin metal coating, it is light and easy to hang on any wall without fear of testing the building’s structural integrity.

When you receive your order, you will notice that it is light weight. Since it is HDU with a thin metal coating, it is light and easy to hang on any wall without fear of testing the building’s structural integrity.

We have our work outside, at the U.S. Coast Guard Academy and at locations all over the world. You will even see our accomplishments at the United States Capitol Visitor Center in Washington which has metal coated HDU in highly visible locations. The same process and materials that we employ are extensively used at the MGM Grand, Bellagio and other Las Vegas properties. In addition to Las Vegas, this patented process in in use from Mexico to Times Square.

In fact, you have probably observed metal coated HDU, but were unaware that you weren’t looking at a foundry casting. Bottom line is architects and designers realize this as a well tested, and well accepted process, and use it without hesitation at some of the worlds most prestigious properties.

Now for the technical stuff:

Our Metal Coating. We utilize LuminOre® exclusively.

- Leach Rate Test Data: 1020 parts per billion

- Weatherometer Test: astm D2565 Completed 3000 hours without any delaminating, corrosion, blistering or breakdown.

- Envirotest Machine: astm D2246 Completed 3000 hours without any delaminating, corrosion, blistering or breakdown.

- Pull Off Strength using Portable Adhesion Tester Type II with a 0-2000 psi scale: astm D4541-95: No coating to substrate failures were reported.

Our HDU Board is from Sign Foam. The following is from their website: Will not warp, split or crack.

100% waterproof.

Will not rot or decompose.

Is highly chemically resistant.

Our HDU Board is from Sign Foam. The following is from their website: Will not warp, split or crack.

100% waterproof.

Will not rot or decompose.

Is highly chemically resistant.

With a signs and plaques from Atlas, you will receive a quality product with the look and many of the characteristics of a foundry cast piece. You will have a truly custom product that is Made In the USA using American materials and labor. You will receive exceptional customer care from the very owners and craftspersons that are creating your selection. We want you to be thrilled with your purchase!

Materials We Use

Materials We Use

The real metal coatings – manufactured by LuminOre and have been proven for over 20 years. These are cold-applied (meaning they wont melt things) REAL METAL coatings that allows a layer of metal to be applied over almost any substrate (surface), in virtually any configuration or design. The incredible results look, feel and act just like hot foundry cast metal but without the weight and expense. Suitable substrates include, but not limited to: laminate, melamine, wood, plastic, gypsum, fiberglass, ceramics, concrete, foam, porcelain, glass and metal.

The metal coating is not paint, it is a patented cold sprayable metalizing process comprised of up to 75% real metal. There is documented ASTM testing with zero breakdown equivalent to 30 years outside. The metal is unaffected by UV exposure, rain, sleet and snow. If left without a clear coat it will tarnish like real metal.

The clearcoats – There are a variety of clearcoats depending on the application. They range from automotive clears, ceramic resin with anti-graffiti properties, to lacquer based. We clear coat all of our signs unless requested otherwise.

The substrate (base material) of our signs – Atlas Signs and Plaques uses 18 to 30 pound – High Density Precision Board (HDU). (Density are available from 10# to 40#) HDU has been in use for over 50 years and was originally designed for insulation in aircraft. It is currently used for insulation of homes, model making, boat building and more specifically in the sign making industry.

The substrate (base material) of our signs – Atlas Signs and Plaques uses 18 to 30 pound – High Density Precision Board (HDU). (Density are available from 10# to 40#) HDU has been in use for over 50 years and was originally designed for insulation in aircraft. It is currently used for insulation of homes, model making, boat building and more specifically in the sign making industry.

The HDU Board is becoming a replacement for the more traditional cedar signs that would be carved or blasted with abrasives. However, the sign board will not split or warp, has no water absorption, so it won’t rot, meaning no insect attacks, and the artistic advantages are limitless.

Enamels – The enamels on our signs are from 1-Shot®. These are the premiere enamels used in sign making for over 50 years. They are for interior and exterior uses.

Metal Muse

Brass – Primarily an alloy of copper and zinc, brass is widely used and well known for its bright, yellow color which is somewhat similar to gold. The metal of choice for makers of musical instruments, polished brass has a ‘sunny’ resonance and is particularly useful where bright decorative design accents are required. Brass is a versatile metal traditionally used for architectural detailing and fixtures, and if required can be gently aged for more classic applications.

Brass – Primarily an alloy of copper and zinc, brass is widely used and well known for its bright, yellow color which is somewhat similar to gold. The metal of choice for makers of musical instruments, polished brass has a ‘sunny’ resonance and is particularly useful where bright decorative design accents are required. Brass is a versatile metal traditionally used for architectural detailing and fixtures, and if required can be gently aged for more classic applications.

While there are a variety of bronzes, the most common alloy is that of copper and tin. Desirable as both a decorative and industrial material bronze has been in use since 4000 years BC. It is harder than copper and forms a very stable surface patina.

Polished bronze is characterized by deep, earthy brown tones with flashes of copper fire; when patinated it displays a variety of subtle black, blue and green colors. Over the years its color and ability to hold detail have made it a favored material for artists and it has been used in the production of some of the worlds most famous art works.

Polished bronze is characterized by deep, earthy brown tones with flashes of copper fire; when patinated it displays a variety of subtle black, blue and green colors. Over the years its color and ability to hold detail have made it a favored material for artists and it has been used in the production of some of the worlds most famous art works.

Copper is perhaps the most familiar of all the metals in common use. Known to some of the oldest civilizations on record, it has a history of use that dates back 10,000 years. Found on the periodic table close to silver and gold, it has many similar characteristics to these precious metals. Associated with Aphrodite, the Greek goddess of love, its rich, lustrous color has for centuries made copper one of the most prized of metals.

Lightly sanded or highly polished to reveal the warmth of its natural ruddy orange color, the metal can also be chemically treated to produce surface patinas in a variety of striking greens and blues. These unique colors are perhaps most familiar when seen on landmark buildings or other structures, such as the Statue of Liberty.

Iron in ancient Mesopotamia iron was more expensive than gold, but today is the most widely used of all metals, and fortunately is also the most abundant, making up 34% of the Earth’s mass.

Iron in ancient Mesopotamia iron was more expensive than gold, but today is the most widely used of all metals, and fortunately is also the most abundant, making up 34% of the Earth’s mass.

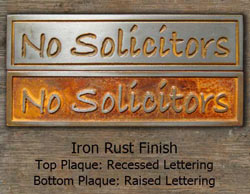

While the metal can be polished to a bright shine, it corrodes quickly. However in the case of the LuminOre coating this can be used to advantage, with the ‘rusted’ finish giving a decorative surface that is rich in oranges and browns, and speckled with fine granular details. Unable to corrode beyond the outer surface, this stabilized finish is suitable for a huge range of applications where an organic industrial or ‘heavy metal’ aesthetic is required. The coating also retains its natural magnetic characteristic.

Silver-Nickel is a silvery white metal that takes on a nice polish and is resistant to oxidation. Known to the ancient Chinese as ‘white copper’, nickel ores were sometimes mistaken for that of silver, and have been in use since 3500BC.

Nickel belongs to the iron group, and is commonly associated with ‘meteoric iron’, having arrived on earth from deep space. It has been suggested that this source accounts for some 30% of the world’s supply of nickel, with the greater part of the rest being concentrated in the Earth’s core.

Clearly this material has exotic origins and is ideal for contemporary applications where a slightly warmer finish than stainless steel is required.

Pewter finished aluminum is best known for its light weight and strength. It is about one third the weight of steel or copper, is easily machined and cast and is used to make millions of different products from the mundane (drink cans) to the exotic (aerospace industry).

Our aluminum can be satin grey, or bright and silvery in appearance when polished; it possesses all the characteristics of foundry-cast aluminum and is indiscernible to touch and sight when compared to the solid metal.

Particularly when satin finished, aluminum has a soft visual character which makes it an ideal alternative to the ‘brashness’ of stainless steel.